Navigating the complexities of a construction project requires a keen eye for detail and an unwavering commitment to quality. Every beam placed, every wire connected, and every finish applied must meet stringent standards to ensure safety, durability, and client satisfaction. This daily vigilance is what defines successful project delivery, preventing costly reworks and potential delays down the line. It is a continuous process of observation, documentation, and correction that builds a foundation of excellence.

In this demanding environment, staying organized and consistent with your quality control efforts is not just good practice, it’s essential. That’s where a structured approach to daily record-keeping comes into play, providing a clear, auditable trail of all QC activities. Imagine having a reliable log that captures every critical check and decision made on-site each day; it’s an invaluable asset for any construction team.

Why a Daily QC Journal is Your Project’s Best Friend

A daily QC journal isn’t just another piece of paperwork; it’s a vital tool for risk mitigation, compliance, and maintaining high standards throughout a construction project. By systematically documenting all quality control activities, you create an irrefutable record of due diligence. This record can be crucial for resolving disputes, demonstrating adherence to specifications, and ensuring regulatory compliance. It acts as an early warning system, allowing teams to identify and address potential quality issues before they escalate into significant problems, saving both time and resources.

Typically, a QC journal captures a snapshot of the day’s quality-related observations, any issues identified, and the corrective actions taken. It serves as a historical account of how quality was managed on a day-to-day basis, reflecting the continuous effort to achieve project excellence. From material inspections to installation verification, every step is scrutinized and documented, ensuring nothing is left to chance. This level of detail not only fosters accountability but also provides a clear pathway for continuous improvement.

Key Elements to Include in Your Template

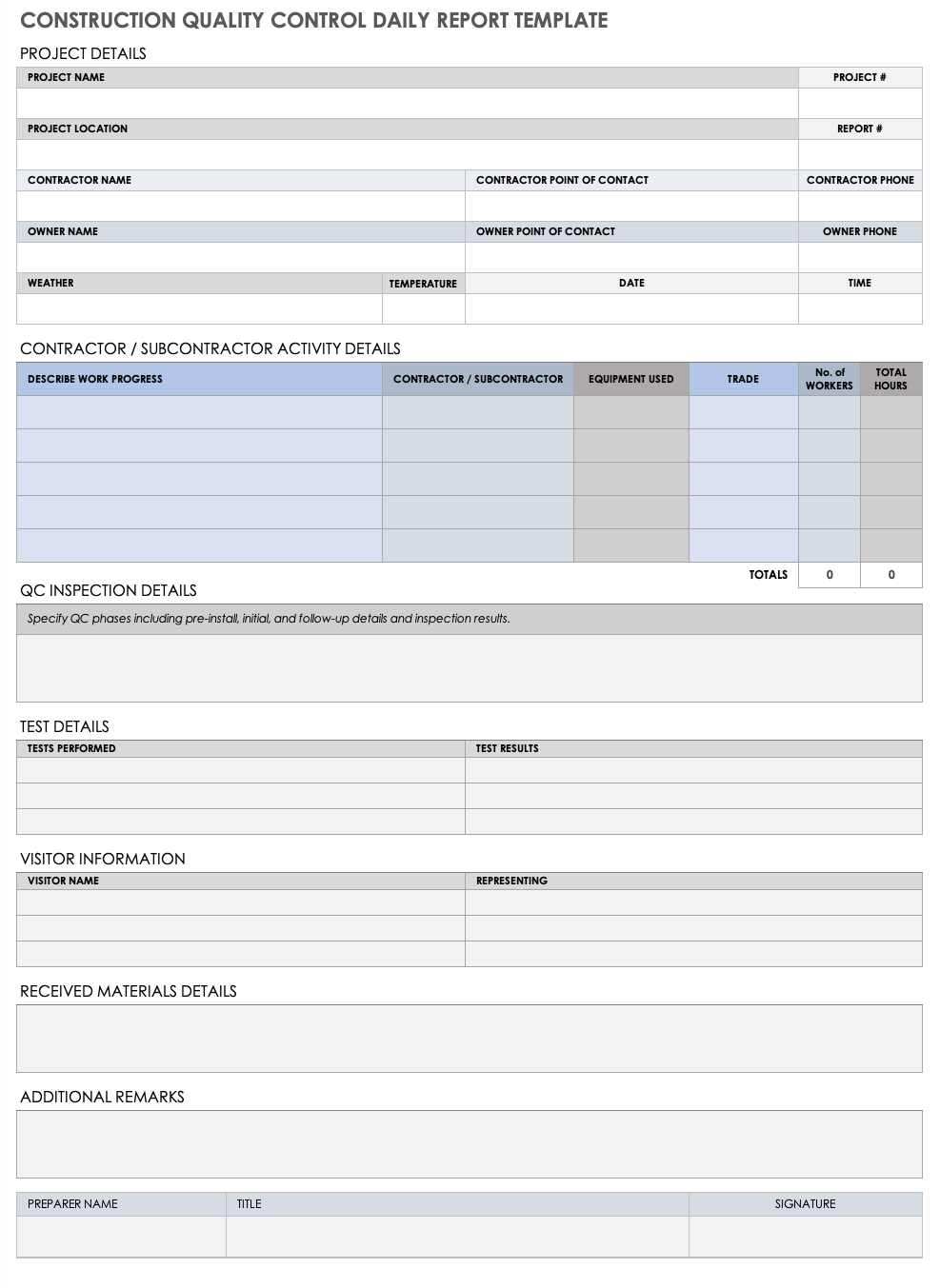

To truly leverage the power of a daily QC journal, it needs to be comprehensive yet easy to use. A well-designed daily construction qc journal template will guide your team through all the necessary checks and ensure no critical information is missed. Here are some key elements that should be part of every effective template:

- Project Name and Number

- Date, Time, and Shift

- Weather Conditions (Temperature, Precipitation)

- On-site Personnel and Key Subcontractors

- Daily Activities Performed and Work Areas

- Specific QC Checks Conducted (e.g., concrete strength, rebar spacing, material approvals)

- Observed Deficiencies or Non-Conformances

- Corrective Actions Taken or Planned

- Equipment Used for QC Checks (e.g., testing equipment, measuring tools)

- Relevant Reference Documents (e.g., drawings, specifications, previous RFI answers)

- Signatures of QC Personnel and Project Management

Structuring these elements within a daily construction qc journal template ensures that every critical piece of information is consistently captured. It streamlines the documentation process, making it less time-consuming and more efficient for the QC team. This consistency also makes the data easier to review, analyze, and retrieve whenever needed, strengthening your project’s overall quality management system.

Making the Most of Your Daily Construction QC Journal Template

Implementing a daily construction qc journal template effectively goes beyond just having the form; it requires a commitment to its consistent and accurate use. Training your team on how to properly fill out the journal, emphasizing the importance of detail and objectivity, is paramount. Whether you opt for a digital solution or a physical binder, accessibility and ease of use will dictate its success. A well-implemented journal becomes an organic part of the daily workflow, not an additional burden.

This journal isn’t just for internal use; it serves as a critical communication tool for all project stakeholders. Clients, architects, engineers, and even regulatory bodies can refer to these daily logs to understand the quality assurance efforts underway. In the event of an inspection or an audit, a meticulously kept journal provides verifiable evidence of compliance and professional conduct. It solidifies trust and transparency, which are invaluable assets in any construction undertaking.

Furthermore, a robust collection of daily QC journals offers a wealth of data for continuous improvement. By reviewing past entries, project managers can identify recurring issues, pinpoint areas needing additional training, or refine processes for future projects. This retrospective analysis transforms raw data into actionable insights, helping to elevate the overall quality standards of your organization and prevent similar problems from arising again.

To maximize the benefits of your daily journal, consider these practical tips:

- Assign clear responsibilities for who completes and reviews the journal entries daily.

- Conduct regular spot checks to ensure entries are thorough, accurate, and submitted on time.

- Store journals securely, whether digitally in cloud storage or physically in a designated archive, ensuring easy retrieval.

- Integrate journal data with other project management software or dashboards for a holistic view of project progress and quality.

- Encourage open discussion during daily briefings about observations recorded in the journal to foster a proactive QC culture.

Maintaining high standards in construction is a continuous journey that demands meticulous attention and systematic documentation. The proactive use of a well-designed daily QC journal is an indispensable asset for any project team striving for excellence and efficiency. It empowers teams to detect and address quality issues promptly, ensuring that every phase of construction aligns with the highest expectations.

Embracing this structured approach to quality control not only minimizes risks and ensures compliance but also fosters a culture of accountability and continuous improvement across the entire project lifecycle. A diligent focus on daily quality records ultimately leads to smoother operations, superior project outcomes, and a strong reputation for delivering construction projects that stand the test of time.